OUR SERVICES

OUR SERVICES

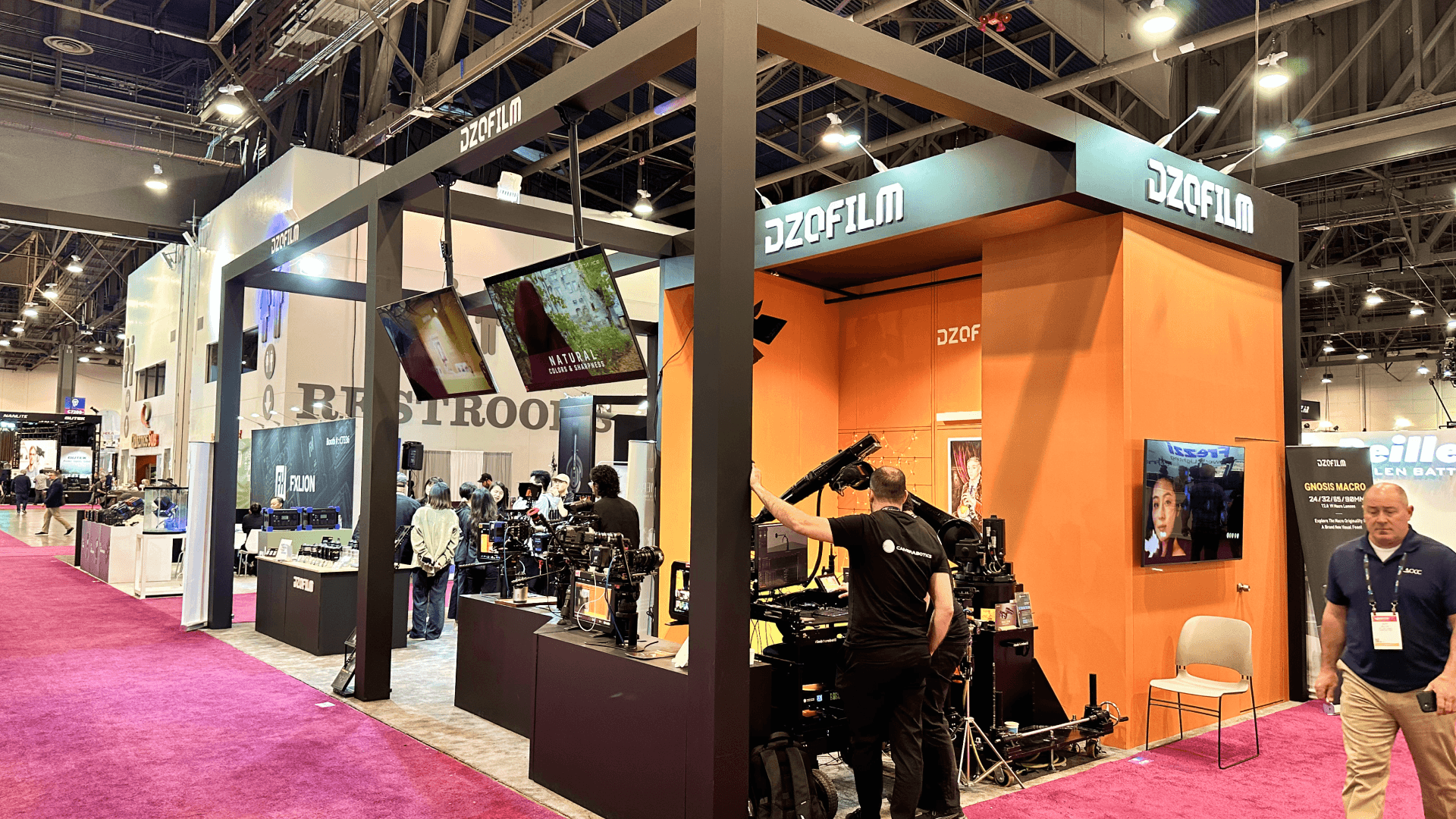

Trade Show Graphics & Brand Presentation

We produce and apply booth graphics and brand elements with execution in mind—so what you approve in design is what shows up on the show floor.

From files and color checks to on-site placement and touch-ups, we keep brand delivery consistent across venues and timelines.

OUR SERVICES

Trade Show Graphics & Brand Presentation

We produce and apply booth graphics and brand elements with execution in mind—so what you approve in design is what shows up on the show floor.

If you need reliable trade show booth design with engineering that actually builds, we align design decisions with real-world constraints to reduce rework and on-site uncertainty.

What’s Included

A clear view of what we produce, how it’s applied on-site, and what’s included in the scope.

Print-ready file prep (bleed, safe area, resolution, panel splits)

Color matching & material selection (Pantone references, substrate notes)

Large-format graphics production (SEG fabric, vinyl, rigid panels—scoped)

Placement mapping (which message goes on which wall, counter, tower, lightbox)

On-site graphic application (alignment, trimming, touch-ups, replacement panels)

Post-show handling notes (reuse labeling, storage prep, next-show refresh)

Learn more about end-to-end delivery: custom trade show booth design and build →

Deliverables You Receive

Deliverables You Receive

Deliverables You Receive

Tangible files, checklists, and placement notes your team can review, approve, and execute against.

Tangible files, checklists, and placement notes your team can review, approve, and execute against.

Graphics Production Plan

A scoped list by area (walls, counters, towers, lightboxes) with sizes, materials, and output specs.

Graphics Production Plan

A scoped list by area (walls, counters, towers, lightboxes) with sizes, materials, and output specs.

Graphics Production Plan

A scoped list by area (walls, counters, towers, lightboxes) with sizes, materials, and output specs.

Print-ready File Checklist

Final proof notes: bleed, safe zones, resolution, fonts/links, and panel naming logic.

Print-ready File Checklist

Final proof notes: bleed, safe zones, resolution, fonts/links, and panel naming logic.

Print-ready File Checklist

Final proof notes: bleed, safe zones, resolution, fonts/links, and panel naming logic.

Color & Material Notes

Pantone/CMYK guidance, substrate behavior notes, and finish expectations (matte/gloss/laminate).

Color & Material Notes

Pantone/CMYK guidance, substrate behavior notes, and finish expectations (matte/gloss/laminate).

Color & Material Notes

Pantone/CMYK guidance, substrate behavior notes, and finish expectations (matte/gloss/laminate).

Placement & Wayfinding Map

Where each visual lives, install order, and labels aligned to booth assembly sequence.

Placement & Wayfinding Map

Where each visual lives, install order, and labels aligned to booth assembly sequence.

Placement & Wayfinding Map

Where each visual lives, install order, and labels aligned to booth assembly sequence.

Install & Touch-up Notes

On-site alignment rules, seam priorities, edge finishing, and quick replacement guidance.

Install & Touch-up Notes

On-site alignment rules, seam priorities, edge finishing, and quick replacement guidance.

Install & Touch-up Notes

On-site alignment rules, seam priorities, edge finishing, and quick replacement guidance.

Reuse & Storage Guidance

How to pack, protect, and store graphics for reuse—plus what to refresh before the next show.

Reuse & Storage Guidance

How to pack, protect, and store graphics for reuse—plus what to refresh before the next show.

Reuse & Storage Guidance

How to pack, protect, and store graphics for reuse—plus what to refresh before the next show.

What Brand Presentation Solves

Graphics aren’t “just printing”—they affect visibility, installation speed, and the final perception of your brand on the show floor.

Graphics aren’t “just printing”—they affect visibility, installation speed, and the final perception of your brand on the show floor.

Graphics aren’t “just printing”—they affect visibility, installation speed, and the final perception of your brand on the show floor.

Cross-material color consistency

We align color expectations across SEG fabric, vinyl, and rigid panels, using Pantone/CMYK references and substrate notes so your booth stays consistent under show-floor lighting.

Cross-material color consistency

We align color expectations across SEG fabric, vinyl, and rigid panels, using Pantone/CMYK references and substrate notes so your booth stays consistent under show-floor lighting.

Cross-material color consistency

We align color expectations across SEG fabric, vinyl, and rigid panels, using Pantone/CMYK references and substrate notes so your booth stays consistent under show-floor lighting.

Print-ready accuracy that prevents reprints

We run print-ready checks (bleed, safe area, resolution, panel splits, font/link packaging) to reduce last-minute file fixes and avoid costly reprints before move-in.

Print-ready accuracy that prevents reprints

We run print-ready checks (bleed, safe area, resolution, panel splits, font/link packaging) to reduce last-minute file fixes and avoid costly reprints before move-in.

Print-ready accuracy that prevents reprints

We run print-ready checks (bleed, safe area, resolution, panel splits, font/link packaging) to reduce last-minute file fixes and avoid costly reprints before move-in.

Readability from aisle distance

We ensure key messages scale correctly for aisle viewing—improving hierarchy, contrast, and placement so visitors can understand your offer within a few seconds.

Readability from aisle distance

We ensure key messages scale correctly for aisle viewing—improving hierarchy, contrast, and placement so visitors can understand your offer within a few seconds.

Readability from aisle distance

We ensure key messages scale correctly for aisle viewing—improving hierarchy, contrast, and placement so visitors can understand your offer within a few seconds.

Placement planning that avoids install conflicts

We map where each graphic lives on the booth—walls, counters, towers, and lightboxes—to prevent conflicts with doors, screens, hardware, and structural details during installation.

Placement planning that avoids install conflicts

We map where each graphic lives on the booth—walls, counters, towers, and lightboxes—to prevent conflicts with doors, screens, hardware, and structural details during installation.

Placement planning that avoids install conflicts

We map where each graphic lives on the booth—walls, counters, towers, and lightboxes—to prevent conflicts with doors, screens, hardware, and structural details during installation.

Faster on-site application & reuse readiness

With install-order labeling and staging notes, crews can apply graphics faster on-site, and you get reuse/storage guidance to protect edges and surfaces for the next show.

Faster on-site application & reuse readiness

With install-order labeling and staging notes, crews can apply graphics faster on-site, and you get reuse/storage guidance to protect edges and surfaces for the next show.

Faster on-site application & reuse readiness

With install-order labeling and staging notes, crews can apply graphics faster on-site, and you get reuse/storage guidance to protect edges and surfaces for the next show.

How We Take Graphics From Files to Show Floor

A practical workflow—from asset intake and print checks to on-site application—built to reduce reprints, delays, and last-minute fixes.

How We Take Graphics From Files to Show Floor

A practical workflow—from asset intake and print checks to on-site application—built to reduce reprints, delays, and last-minute fixes.

How We Take Graphics From Files to Show Floor

A practical workflow—from asset intake and print checks to on-site application—built to reduce reprints, delays, and last-minute fixes.

Step 1

Asset intake & message priority

Collect brand files and define which messages must be dominant at aisle distance.

Step 2

File review & print-ready prep

Confirm resolution, bleeds, safe zones, panel splits, and production constraints.

Step 3

Material selection & color expectation

Choose substrates and finishes that match the booth surfaces and lighting conditions.

Step 4

Production + labeling + staging

Produce graphics, label by install order, and stage components for shipment or on-site delivery.

Step 5

On-site application & final touch-ups

Align, trim, and finish edges on-site—handling last-minute swaps or replacement panels if needed.

Step 1

Asset intake & message priority

Collect brand files and define which messages must be dominant at aisle distance.

Step 2

File review & print-ready prep

Confirm resolution, bleeds, safe zones, panel splits, and production constraints.

Step 3

Material selection & color expectation

Choose substrates and finishes that match the booth surfaces and lighting conditions.

Step 4

Production + labeling + staging

Produce graphics, label by install order, and stage components for shipment or on-site delivery.

Step 5

On-site application & final touch-ups

Align, trim, and finish edges on-site—handling last-minute swaps or replacement panels if needed.

Step 1

Asset intake & message priority

Collect brand files and define which messages must be dominant at aisle distance.

Step 2

File review & print-ready prep

Confirm resolution, bleeds, safe zones, panel splits, and production constraints.

Step 3

Material selection & color expectation

Choose substrates and finishes that match the booth surfaces and lighting conditions.

Step 4

Production + labeling + staging

Produce graphics, label by install order, and stage components for shipment or on-site delivery.

Step 5

On-site application & final touch-ups

Align, trim, and finish edges on-site—handling last-minute swaps or replacement panels if needed.

What We Need From You

Clear inputs help us keep production accurate and avoid last-minute changes during printing and on-site application.

Brand guidelines (logo usage, colors, fonts)

Source files (AI/PDF/SVG + high-res images)

Key messages and priority order

Any mandatory legal/disclaimer text

Deadline and shipping / move-in constraints

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Related Pages

Related Pages

View Case Studies

Explore real booth builds by size, complexity, and execution approach.

Back to Services

Back to Services

Back to Services

View all service modules and end-to-end delivery scope.

Browse Trade Shows

Planning notes and venue considerations for major trade shows.

Las Vegas Execution Reference

Local labor rules, drayage flow, and on-site coordination in Las Vegas.

Frequently Asked Questions

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Quick clarity on build readiness, timelines, and pre-build checkpoints.

When should we start graphics planning before the show?

Ideally 3–6 weeks out, depending on approvals and shipping windows. Earlier is safer for complex builds or multi-piece branding.

What file formats do you need for printing?

Vector files (AI/PDF/SVG) for logos and text, plus high-resolution images. We’ll verify bleed, safe area, and resolution before production.

Can you match our brand colors exactly?

We align expectations based on material and venue lighting. We can target closest matches and confirm practical color ranges before producing.

Do you handle on-site application and touch-ups?

Yes—application, alignment, and touch-ups can be included so graphics land cleanly with seams, edges, and show-floor constraints.

What if the venue has restrictions on adhesives or hanging signage?

We review venue constraints early and adjust materials or installation methods to fit rules and labor coordination.

Can graphics be packed for reuse at the next show?

Yes—labeling, protection, and packing guidance can be included to reduce damage and make reuse easier next time.

When should we start graphics planning before the show?

Ideally 3–6 weeks out, depending on approvals and shipping windows. Earlier is safer for complex builds or multi-piece branding.

What file formats do you need for printing?

Vector files (AI/PDF/SVG) for logos and text, plus high-resolution images. We’ll verify bleed, safe area, and resolution before production.

Can you match our brand colors exactly?

We align expectations based on material and venue lighting. We can target closest matches and confirm practical color ranges before producing.

Do you handle on-site application and touch-ups?

Yes—application, alignment, and touch-ups can be included so graphics land cleanly with seams, edges, and show-floor constraints.

What if the venue has restrictions on adhesives or hanging signage?

We review venue constraints early and adjust materials or installation methods to fit rules and labor coordination.

Can graphics be packed for reuse at the next show?

Yes—labeling, protection, and packing guidance can be included to reduce damage and make reuse easier next time.

When should we start graphics planning before the show?

Ideally 3–6 weeks out, depending on approvals and shipping windows. Earlier is safer for complex builds or multi-piece branding.

What file formats do you need for printing?

Vector files (AI/PDF/SVG) for logos and text, plus high-resolution images. We’ll verify bleed, safe area, and resolution before production.

Can you match our brand colors exactly?

We align expectations based on material and venue lighting. We can target closest matches and confirm practical color ranges before producing.

Do you handle on-site application and touch-ups?

Yes—application, alignment, and touch-ups can be included so graphics land cleanly with seams, edges, and show-floor constraints.

What if the venue has restrictions on adhesives or hanging signage?

We review venue constraints early and adjust materials or installation methods to fit rules and labor coordination.

Can graphics be packed for reuse at the next show?

Yes—labeling, protection, and packing guidance can be included to reduce damage and make reuse easier next time.

Ready to align your booth visuals with real execution?

Ready to align your booth visuals with real execution?

Share your booth size, brand files, and timeline—we’ll break production into deliverables and an install-ready plan.

Visit: Circle Exhibit →