OUR SERVICES

OUR SERVICES

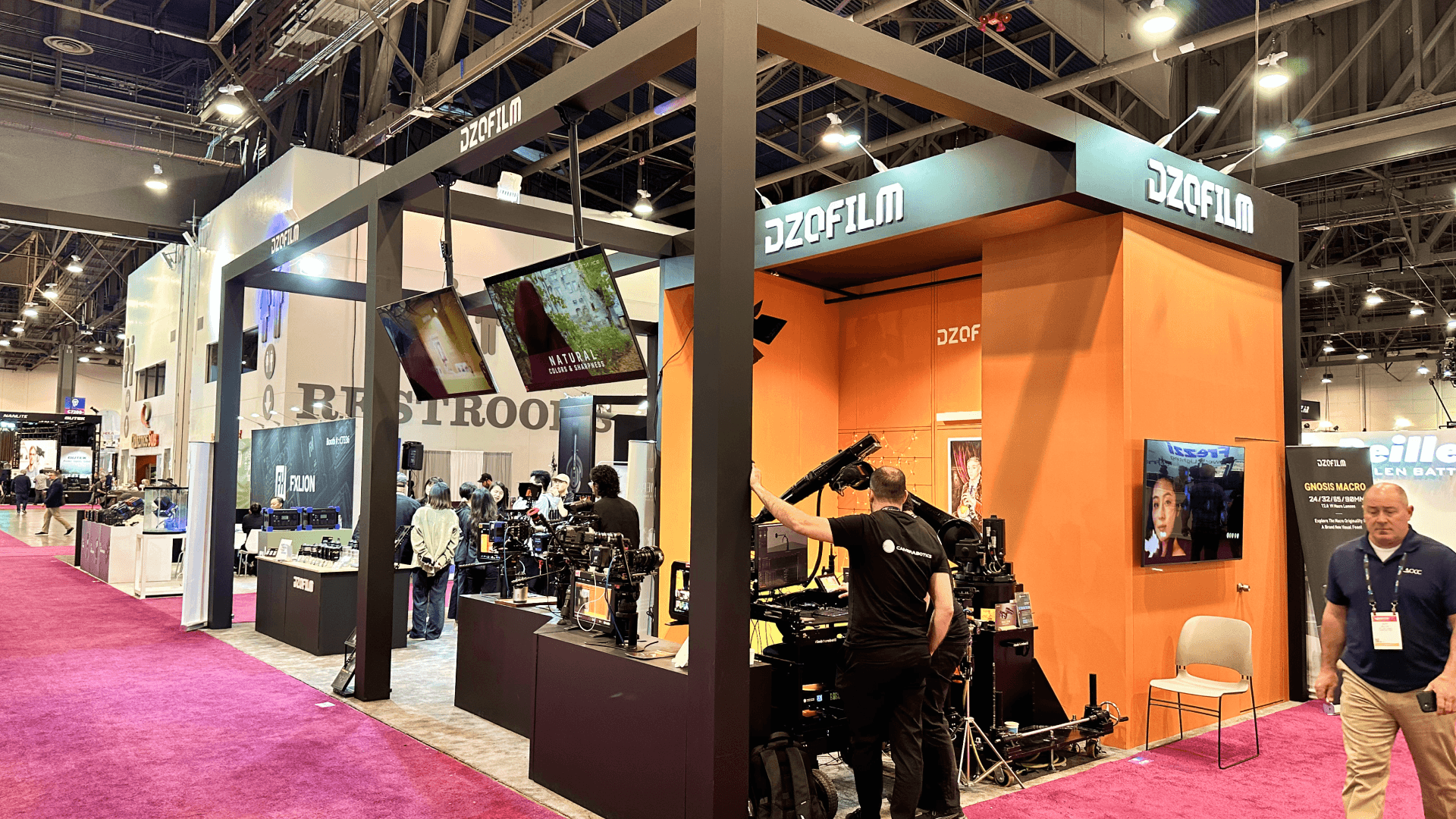

Trade Show Booth Design & Engineering

From layout and 3D direction to buildable engineering and production-ready drawings—we make the concept deliverable for fabrication, shipping, and installation.Engineered for fabrication accuracy, shipping constraints, and on-site installation.

If you need reliable trade show booth design with engineering that actually builds, we align design decisions with real-world constraints to reduce rework and on-site uncertainty.

OUR SERVICES

Trade Show Booth Design & Engineering

From layout and 3D direction to buildable engineering and production-ready drawings—we make the concept deliverable for fabrication, shipping, and installation.Engineered for fabrication accuracy, shipping constraints, and on-site installation.

If you need reliable trade show booth design with engineering that actually builds, we align design decisions with real-world constraints to reduce rework and on-site uncertainty.

Design + Engineering Deliverables You Can Execute

Layout planning & traffic flow

3D concept direction

Structure & materials approach

Buildability checks

Production-ready drawings and key details

Execution checklist for fabrication, logistics, and installation handoff

Need end-to-end delivery? See custom trade show booth design and build→.

What the Design Phase Covers

What the Design Phase Covers

A location-specific workflow built to handle Las Vegas venue rules, union labor, and tight move-in schedules.

A location-specific workflow built to handle Las Vegas venue rules, union labor, and tight move-in schedules.

A location-specific workflow built to handle Las Vegas venue rules, union labor, and tight move-in schedules.

1

Objectives alignment

Objectives alignment

Objectives alignment

exhibit items, messaging hierarchy, engagement needs

exhibit items, messaging hierarchy, engagement needs

2

Layout planning

Layout planning

Layout planning

entrances, focal points, demo/meeting/storage zones

entrances, focal points, demo/meeting/storage zones

3

Brand presentation

Brand presentation

Brand presentation

key surfaces, signage system, finish & lighting direction

key surfaces, signage system, finish & lighting direction

4

Configuration fit

Configuration fit

Configuration fit

inline / corner / island flow and openings

inline / corner / island flow and openings

5

Delivery standards

Delivery standards

Delivery standards

version control, output formats, review milestones

version control, output formats, review milestones

What Engineering Solves

What Engineering Solves

Structural logic for on-site stability (connections, key nodes)

Structural logic for on-site stability (connections, key nodes)

Structural logic for on-site stability (connections, key nodes)

Materials and fabrication feasibility based on build constraints

Materials and fabrication feasibility based on build constraints

Materials and fabrication feasibility based on build constraints

Modular breakdown for freight handling and fast on-site assembly

Modular breakdown for freight handling and fast on-site assembly

Modular breakdown for freight handling and fast on-site assembly

Execution readiness defined before move-in (sequence and checkpoints)

Execution readiness defined before move-in (sequence and checkpoints)

Execution readiness defined before move-in (sequence and checkpoints)

Risk surfacing for complex builds (spans, custom shapes, special finishes)

Risk surfacing for complex builds (spans, custom shapes, special finishes)

Risk surfacing for complex builds (spans, custom shapes, special finishes)

How We Move From Concept to Buildable

Clear milestones that connect design, engineering, fabrication alignment, and execution handoff—so each step produces usable deliverables.

Scope Alignment

Align goals, exhibit items, required zones, and timeline. Confirm booth configuration (inline/corner/island) and key constraints to set scope boundaries and priorities.

Layout + 3D Direction

Produce layout and traffic-flow logic, define focal surfaces, entry strategy, and zone organization. Iterate with 3D direction early to lock overall form and brand presentation.

Engineering Development

Translate design into buildable structure/material logic—connections, critical load points, finish details, and modular breakdown—then produce production-ready drawings and key details.

Fabrication Alignment

Align production schedule, assembly sequence, and checkpoints. Define where pre-build verification and QC are required so what’s fabricated can be installed reliably on-site.

Execution Handoff

Deliver a handoff package (assembly logic, packing notes, risk flags, milestone checks) so fabrication, logistics, and install teams can take over seamlessly and stay on track.

If timelines are tight, we can lock layout/3D direction first and run engineering in parallel with fabrication alignment.

How We Move From Concept to Buildable

Clear milestones that connect design, engineering, fabrication alignment, and execution handoff—so each step produces usable deliverables.

Scope Alignment

Align goals, exhibit items, required zones, and timeline. Confirm booth configuration (inline/corner/island) and key constraints to set scope boundaries and priorities.

Layout + 3D Direction

Produce layout and traffic-flow logic, define focal surfaces, entry strategy, and zone organization. Iterate with 3D direction early to lock overall form and brand presentation.

Engineering Development

Translate design into buildable structure/material logic—connections, critical load points, finish details, and modular breakdown—then produce production-ready drawings and key details.

Fabrication Alignment

Align production schedule, assembly sequence, and checkpoints. Define where pre-build verification and QC are required so what’s fabricated can be installed reliably on-site.

Execution Handoff

Deliver a handoff package (assembly logic, packing notes, risk flags, milestone checks) so fabrication, logistics, and install teams can take over seamlessly and stay on track.

If timelines are tight, we can lock layout/3D direction first and run engineering in parallel with fabrication alignment.

How We Move From Concept to Buildable

Clear milestones that connect design, engineering, fabrication alignment, and execution handoff—so each step produces usable deliverables.

Scope Alignment

Align goals, exhibit items, required zones, and timeline. Confirm booth configuration (inline/corner/island) and key constraints to set scope boundaries and priorities.

Layout + 3D Direction

Produce layout and traffic-flow logic, define focal surfaces, entry strategy, and zone organization. Iterate with 3D direction early to lock overall form and brand presentation.

Engineering Development

Translate design into buildable structure/material logic—connections, critical load points, finish details, and modular breakdown—then produce production-ready drawings and key details.

Fabrication Alignment

Align production schedule, assembly sequence, and checkpoints. Define where pre-build verification and QC are required so what’s fabricated can be installed reliably on-site.

Execution Handoff

Deliver a handoff package (assembly logic, packing notes, risk flags, milestone checks) so fabrication, logistics, and install teams can take over seamlessly and stay on track.

If timelines are tight, we can lock layout/3D direction first and run engineering in parallel with fabrication alignment.

What We Need From You

The more complete these inputs are, the faster we can finalize layout and buildable engineering with fewer iterations.

Booth Size & Configuration

Share booth size, configuration (inline/corner/island), and any known openings, orientations, or constraints.

Exhibit Items List (Dimensions/Weights)

Especially for equipment or heavy items, provide dimensions, weights, and demo/power needs to prevent structural and layout rework later.

Brand Assets

Logo, fonts, key visuals, brand colors, and any brand guidelines (a brand guide helps).

Functional Zones

Define required zones—display, meeting, demo/engagement, storage/back-of-house, reception—and their priority.

Audience & Use Scenario

Who is the target audience and what should happen in the booth (demo, hands-on, meetings, lead capture)? This shapes flow and space planning.

Timeline & Milestones

Provide desired dates for design rounds, final approval, production window, shipping date, and move-in/move-out windows (if known).

On-site Constraints (If Any)

Share known height limits, rigging/electrical needs, installation constraints, or special requirements (materials, structure types, etc.).

If you don’t have everything yet, share what you know—we’ll help fill gaps through an execution-focused scope review.

Deliverables

Deliverables

Scope-dependent. Below are typical deliverables designed for fabrication, shipping, and on-site installation handoff.

Scope-dependent. Below are typical deliverables designed for fabrication, shipping, and on-site installation handoff.

Layout Plan

A floor plan defining openings, traffic flow, key zones (demo/meeting/storage/engagement), and focal points.

Layout Plan

A floor plan defining openings, traffic flow, key zones (demo/meeting/storage/engagement), and focal points.

Layout Plan

A floor plan defining openings, traffic flow, key zones (demo/meeting/storage/engagement), and focal points.

3D Views

3D perspectives to confirm overall form, brand-facing surfaces, finish direction, and lighting intent.

3D Views

3D perspectives to confirm overall form, brand-facing surfaces, finish direction, and lighting intent.

3D Views

3D perspectives to confirm overall form, brand-facing surfaces, finish direction, and lighting intent.

Finish / Material Notes

Material selections, surface treatments, color/texture direction to keep fabrication consistent and buildable.

Finish / Material Notes

Material selections, surface treatments, color/texture direction to keep fabrication consistent and buildable.

Finish / Material Notes

Material selections, surface treatments, color/texture direction to keep fabrication consistent and buildable.

Production-Ready Drawings & Key Details

Structural logic, connection methods, and critical load/finish details to make the design fabrication- and assembly-ready.

Production-Ready Drawings & Key Details

Structural logic, connection methods, and critical load/finish details to make the design fabrication- and assembly-ready.

Production-Ready Drawings & Key Details

Structural logic, connection methods, and critical load/finish details to make the design fabrication- and assembly-ready.

Modular Breakdown & Assembly Logic

Breakdown strategy, assembly sequence, and key notes for packing efficiency and faster on-site installation.

Modular Breakdown & Assembly Logic

Breakdown strategy, assembly sequence, and key notes for packing efficiency and faster on-site installation.

Modular Breakdown & Assembly Logic

Breakdown strategy, assembly sequence, and key notes for packing efficiency and faster on-site installation.

Execution Handoff Checklist

A checklist for fabrication/logistics/install teams—materials notes, checkpoints, risk flags, and milestone confirmations.

Execution Handoff Checklist

A checklist for fabrication/logistics/install teams—materials notes, checkpoints, risk flags, and milestone confirmations.

Execution Handoff Checklist

A checklist for fabrication/logistics/install teams—materials notes, checkpoints, risk flags, and milestone confirmations.

Execution & Compliance

Execution & Compliance

Venue rules, move-in windows, union labor coordination, rigging/electrical needs, and structural requirements vary by city and venue. We account for these constraints during engineering development to reduce rework and on-site uncertainty.

Venue rules, move-in windows, union labor coordination, rigging/electrical needs, and structural requirements vary by city and venue. We account for these constraints during engineering development to reduce rework and on-site uncertainty.

For Las Vegas projects (reference only):

For Las Vegas projects (reference only):

For 20' x 30' (600 sq. ft.)

DevLearn 2023

Blinkist

20×30 booth for Blinkist at DevLearn 2023, designed for clear brand visibility, controlled circulation, and fast, repeatable product demos.

MGM Grand, Las Vegas, NV

For 30' x 30' (900 sq. ft.)

SupplySide West (SSW) 2024

EF (Effepharm)

A 30×30 nutraceutical and biotech booth case study at SSW 2024, highlighting exhibit execution, acrylic fabrication, open-layout planning, and on-site delivery.

Mandalay Bay, Las Vegas, NV

For 20' x 40' (800 sq. ft.)

SSW 2024 (SupplySide West)

Novonesis

Custom 20×40 exhibit booth for a biosolutions and probiotics brand at SSW 2024, demonstrating sustainable materials, modular structure, and show-floor execution for bioscience-focused presentations.

Mandalay Bay, Las Vegas, NV

For 20' x 30' (600 sq. ft.)

DevLearn 2023

Blinkist

20×30 booth for Blinkist at DevLearn 2023, designed for clear brand visibility, controlled circulation, and fast, repeatable product demos.

MGM Grand, Las Vegas, NV

For 20' x 40' (800 sq. ft.)

SSW 2024 (SupplySide West)

Novonesis

Custom 20×40 exhibit booth for a biosolutions and probiotics brand at SSW 2024, demonstrating sustainable materials, modular structure, and show-floor execution for bioscience-focused presentations.

Mandalay Bay, Las Vegas, NV

For 30' x 30' (900 sq. ft.)

SupplySide West (SSW) 2024

EF (Effepharm)

A 30×30 nutraceutical and biotech booth case study at SSW 2024, highlighting exhibit execution, acrylic fabrication, open-layout planning, and on-site delivery.

Mandalay Bay, Las Vegas, NV

For 20×20 island booth

VRMA International Conference 2024

Rise & Shine by Inhabitat

A 20×20 experiential booth case study for Rise & Shine by Inhabitat at VRMA 2024, highlighting open layout planning, studio-style touchpoints, and show-floor engagement flow.

Phoenix Convention Center, AZ

For 20' x 30' (600 sq. ft.)

DevLearn 2023

Blinkist

20×30 booth for Blinkist at DevLearn 2023, designed for clear brand visibility, controlled circulation, and fast, repeatable product demos.

MGM Grand, Las Vegas, NV

For 30' x 30' (900 sq. ft.)

SupplySide West (SSW) 2024

EF (Effepharm)

A 30×30 nutraceutical and biotech booth case study at SSW 2024, highlighting exhibit execution, acrylic fabrication, open-layout planning, and on-site delivery.

Mandalay Bay, Las Vegas, NV

Proof of Delivery

Explore real project outcomes across different booth sizes, build complexity, and on-site execution methods:

For higher-complexity builds, we recommend an early engineering + logistics review to lock risks during the build phase.

Proof of Delivery

Explore real project outcomes across different booth sizes, build complexity, and on-site execution methods:

For higher-complexity builds, we recommend an early engineering + logistics review to lock risks during the build phase.

Proof of Delivery

Explore real project outcomes across different booth sizes, build complexity, and on-site execution methods:

For higher-complexity builds, we recommend an early engineering + logistics review to lock risks during the build phase.

Related Links

Related Links

View Case Studies

See delivered projects across booth sizes and build complexity.

Back to Services

View all service modules and end-to-end delivery scope.

Browse Trade Shows

Explore trade show pages for context and execution considerations.

Las Vegas Execution Reference

Notes on local coordination, move-in windows, and on-site execution.

FAQ

FAQs

Quick clarity on scope, timeline, and execution workflow

Do you offer design-only services?

Yes. We can deliver design-only, engineering-only, or combined scopes. To keep execution reliable, we recommend at least core buildability checks and key detailing.

Do you offer design-only services?

Yes. We can deliver design-only, engineering-only, or combined scopes. To keep execution reliable, we recommend at least core buildability checks and key detailing.

Do you offer design-only services?

Yes. We can deliver design-only, engineering-only, or combined scopes. To keep execution reliable, we recommend at least core buildability checks and key detailing.

If my team already has a concept, can you handle engineering?

If my team already has a concept, can you handle engineering?

If my team already has a concept, can you handle engineering?

Do you consider shipping and installation during design?

Do you consider shipping and installation during design?

Do you consider shipping and installation during design?

What “execution-ready” deliverables do you provide?

What “execution-ready” deliverables do you provide?

What “execution-ready” deliverables do you provide?

How do you reduce risk for complex structures or heavy exhibits?

How do you reduce risk for complex structures or heavy exhibits?

How do you reduce risk for complex structures or heavy exhibits?

How early should I start Design & Engineering?

How early should I start Design & Engineering?

How early should I start Design & Engineering?

Contact

Ready to turn your concept into a buildable plan?

Ready to turn your concept into a buildable plan?

Share your booth specs, exhibit items, and timeline—we’ll align deliverables and engineering milestones for reliable execution.

Share your booth specs, exhibit items, and timeline—we’ll align deliverables and engineering milestones for reliable execution.

Share your booth specs, exhibit items, and timeline—we’ll align deliverables and engineering milestones for reliable execution.

Visit: Circle Exhibit →