Trade Show Booth Fabrication & Pre-build Checks

Build-ready structures with verification before the show—reducing on-site rework, delays, and compliance risk.

Fabrication is where a booth either becomes a predictable system—or becomes an on-site problem. We break designs into buildable modules, produce components with practical tolerances, and run pre-build checkpoints to confirm fit, stability, and access details before shipping.Pre-build checkpoints cover fit, alignment, stability, and access clearances before shipping.

Trade Show Booth Fabrication & Pre-build Checks

Build-ready structures with verification before the show—reducing on-site rework, delays, and compliance risk.

If you need reliable trade show booth design with engineering that actually builds, we align design decisions with real-world constraints to reduce rework and on-site uncertainty.

What Fabrication & Pre-build Checks Include

This module focuses on turning approved design intent into fabrication-ready parts and verifying critical points before the booth reaches the show floor.

Build plan setup: module breakdown, connection logic, material plan

Fabrication execution: frames, walls, counters, specialty elements (as scoped)

Pre-build checkpoints: fit, alignment, stability, door/access clearances

Finish + detail verification: edge quality, visible seams, hardware placement

Labeling system: module IDs aligned to install sequence

Packing plan: protection, order, and a clear packing list for crews

Deliverables You Receive

Deliverables You Receive

Deliverables You Receive

We package fabrication outputs as install-ready modules—so your crew (or venue labor) can assemble with less uncertainty.

We package fabrication outputs as install-ready modules—so your crew (or venue labor) can assemble with less uncertainty.

Fabricated Modules

Build-ready sections produced to practical tolerances—frames, walls, counters, and scoped custom parts.

Fabricated Modules

Build-ready sections produced to practical tolerances—frames, walls, counters, and scoped custom parts.

Fabricated Modules

Build-ready sections produced to practical tolerances—frames, walls, counters, and scoped custom parts.

Connection & Assembly Notes

A clear “what-connects-to-what” guide so crews can assemble without guessing on-site.

Connection & Assembly Notes

A clear “what-connects-to-what” guide so crews can assemble without guessing on-site.

Connection & Assembly Notes

A clear “what-connects-to-what” guide so crews can assemble without guessing on-site.

Module Labeling System

Consistent IDs aligned to the install sequence, making unpacking and staging faster.

Module Labeling System

Consistent IDs aligned to the install sequence, making unpacking and staging faster.

Module Labeling System

Consistent IDs aligned to the install sequence, making unpacking and staging faster.

Packing List & Protection Plan

What’s in each box/crate, plus protection notes to reduce damage during drayage and handling.

Packing List & Protection Plan

What’s in each box/crate, plus protection notes to reduce damage during drayage and handling.

Packing List & Protection Plan

What’s in each box/crate, plus protection notes to reduce damage during drayage and handling.

Pre-build Check Notes

Key confirmations (fit, alignment, stability) and a closed issue log before the booth ships.

Pre-build Check Notes

Key confirmations (fit, alignment, stability) and a closed issue log before the booth ships.

Pre-build Check Notes

Key confirmations (fit, alignment, stability) and a closed issue log before the booth ships.

Install Readiness Handoff

Risk points and install tips summarized for venue labor or your on-site team—so execution stays predictable.

Install Readiness Handoff

Risk points and install tips summarized for venue labor or your on-site team—so execution stays predictable.

Install Readiness Handoff

Risk points and install tips summarized for venue labor or your on-site team—so execution stays predictable.

Quality Control Before the Show Floor

Pre-build checks are not cosmetic—they’re a practical way to avoid on-site delays when move-in windows are short and labor rules are strict.

Pre-build checks are not cosmetic—they’re a practical way to avoid on-site delays when move-in windows are short and labor rules are strict.

Pre-build checks are not cosmetic—they’re a practical way to avoid on-site delays when move-in windows are short and labor rules are strict.

Fit & Alignment

Confirm critical dimensions, edge alignment, panel gaps, and door/access clearances before packing.

Fit & Alignment

Confirm critical dimensions, edge alignment, panel gaps, and door/access clearances before packing.

Fit & Alignment

Confirm critical dimensions, edge alignment, panel gaps, and door/access clearances before packing.

Structural Readiness

Verify stability, connection strength, and practical assembly logic for predictable installation.

Structural Readiness

Verify stability, connection strength, and practical assembly logic for predictable installation.

Structural Readiness

Verify stability, connection strength, and practical assembly logic for predictable installation.

Finish & Detail Verification

Check paint/laminate consistency, edge quality, hardware placement, and visible seam control.

Finish & Detail Verification

Check paint/laminate consistency, edge quality, hardware placement, and visible seam control.

Finish & Detail Verification

Check paint/laminate consistency, edge quality, hardware placement, and visible seam control.

Install Timing Protection

Labeling and packing order are aligned to move-in schedules so crews can install without searching or re-sorting.

Install Timing Protection

Labeling and packing order are aligned to move-in schedules so crews can install without searching or re-sorting.

Install Timing Protection

Labeling and packing order are aligned to move-in schedules so crews can install without searching or re-sorting.

Compliance Risk Surfacing

Surface venue rules, union labor boundaries, and rigging/electrical constraints early to avoid last-minute changes.

Compliance Risk Surfacing

Surface venue rules, union labor boundaries, and rigging/electrical constraints early to avoid last-minute changes.

Compliance Risk Surfacing

Surface venue rules, union labor boundaries, and rigging/electrical constraints early to avoid last-minute changes.

How We Move From Plan to Build-Ready Fabrication

A simple workflow that keeps production on schedule and reduces on-site uncertainty.

How We Move From Plan to Build-Ready Fabrication

A simple workflow that keeps production on schedule and reduces on-site uncertainty.

How We Move From Plan to Build-Ready Fabrication

A simple workflow that keeps production on schedule and reduces on-site uncertainty.

Step 1

Scope confirmation & file handoff

Confirm booth size, key elements, finishes, and what’s included in fabrication. Align on timeline and approval cadence.

Step 2

Material + finish alignment

Select materials and finish approach that match durability, shipping reality, and on-site handling constraints.

Step 3

Module breakdown + fabrication scheduling

Break the booth into install-ready modules and define connection logic so assembly is predictable.

Step 4

Pre-build checkpoints + issue log

Run fit/alignment/stability checks, record issues, and close adjustments before packing.

Step 5

Labeling, packing list, ship-ready release

Label modules, pack by install order, provide packing list, and release for shipping or on-site delivery.

Step 1

Scope confirmation & file handoff

Confirm booth size, key elements, finishes, and what’s included in fabrication. Align on timeline and approval cadence.

Step 2

Material + finish alignment

Select materials and finish approach that match durability, shipping reality, and on-site handling constraints.

Step 3

Module breakdown + fabrication scheduling

Break the booth into install-ready modules and define connection logic so assembly is predictable.

Step 4

Pre-build checkpoints + issue log

Run fit/alignment/stability checks, record issues, and close adjustments before packing.

Step 5

Labeling, packing list, ship-ready release

Label modules, pack by install order, provide packing list, and release for shipping or on-site delivery.

Step 1

Scope confirmation & file handoff

Confirm booth size, key elements, finishes, and what’s included in fabrication. Align on timeline and approval cadence.

Step 2

Material + finish alignment

Select materials and finish approach that match durability, shipping reality, and on-site handling constraints.

Step 3

Module breakdown + fabrication scheduling

Break the booth into install-ready modules and define connection logic so assembly is predictable.

Step 4

Pre-build checkpoints + issue log

Run fit/alignment/stability checks, record issues, and close adjustments before packing.

Step 5

Labeling, packing list, ship-ready release

Label modules, pack by install order, provide packing list, and release for shipping or on-site delivery.

What We Need From You

What We Need From You

The clearer the inputs, the fewer last-minute changes happen during fabrication and pre-build checks.

Booth size and show location (city/venue if known)

Target move-in date / exhibit schedule (even an estimate helps)

Brand assets: logos, fonts, color references, visual guidelines

Must-have functional needs: demo weight, power needs, storage, security

Finish preferences: reference photos or sample expectations

Approval owner + response timing (who signs off and how fast)

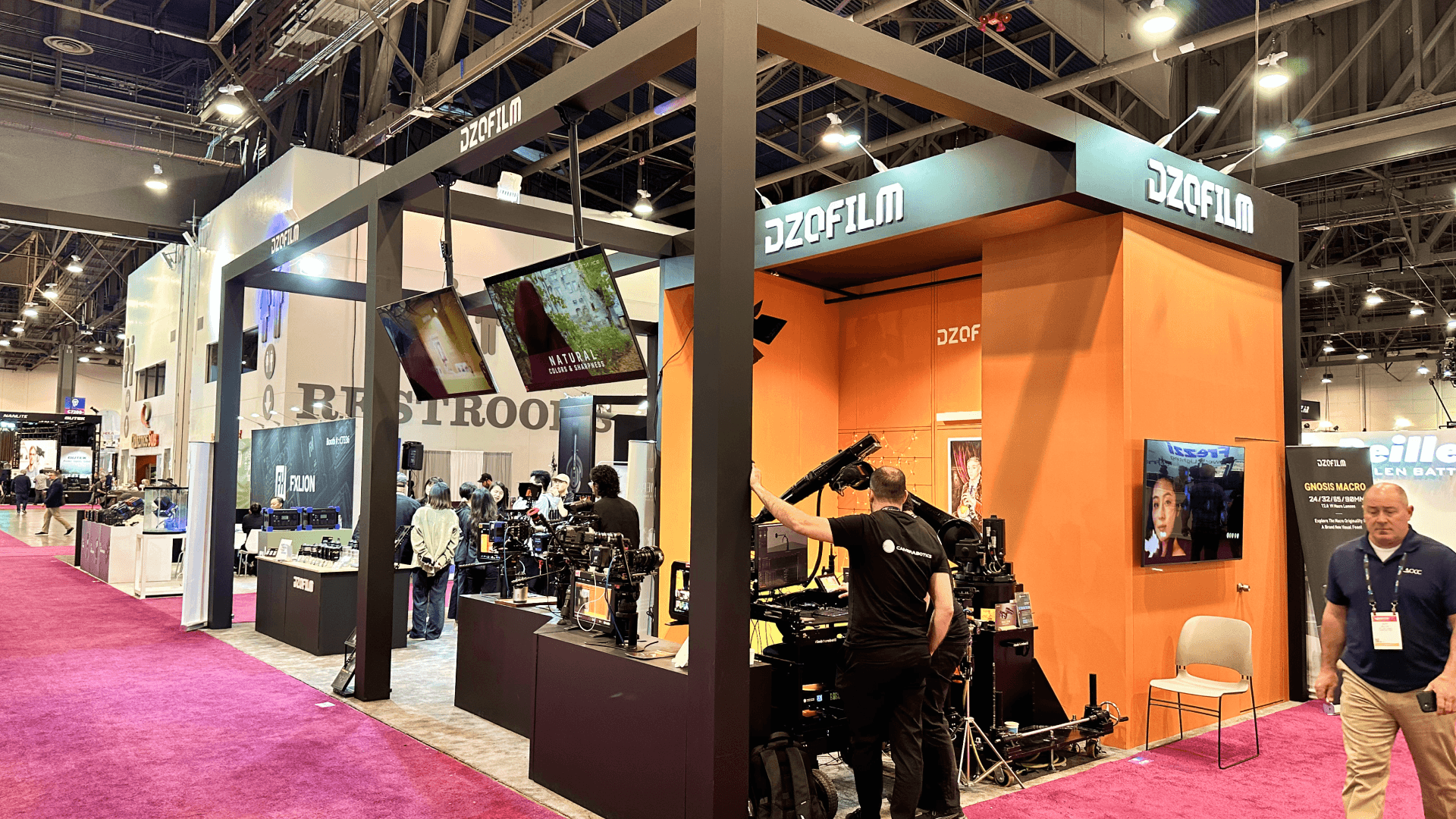

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Proof of Delivery

See projects where pre-build verification reduced on-site adjustments and helped installation stay on schedule under tight move-in windows.

Related Pages

Related Pages

View Case Studies

Explore real booth builds by size, complexity, and execution approach.

Back to Services

Back to Services

Back to Services

View all service modules and end-to-end delivery scope.

Browse Trade Shows

Planning notes and venue considerations for major trade shows.

Las Vegas Execution Reference

Local labor rules, drayage flow, and on-site coordination in Las Vegas.

Frequently Asked Questions

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Can you fabricate a booth based on an existing design file?

Yes. We review buildability (materials, connections, tolerances) and convert the design into a fabrication-ready module plan before production.

What exactly happens in a pre-build check?

We verify fit, alignment, stability, and access details (doors, panels, clearances). Any issues are logged and corrected before packing.Typical checkpoints include hardware alignment, panel seams, and access clearances.

How early should fabrication start before a show?

Earlier is safer for custom builds. Pre-build checks also require buffer time for adjustments before packing and shipping.

Can you fabricate only specific parts (counters, walls, frames)?

Yes. We can fabricate selected modules as long as interfaces and connection logic are defined for on-site integration.

How do you package modules for faster installation?

We label modules, align packing order with the install sequence, and provide a packing list so crews can unpack in the right order.

What if the venue has strict rules (union labor, move-in windows)?

We surface constraints early and adapt build logic, labeling, and install sequencing so execution stays predictable under tight windows.

Can you fabricate a booth based on an existing design file?

Yes. We review buildability (materials, connections, tolerances) and convert the design into a fabrication-ready module plan before production.

What exactly happens in a pre-build check?

We verify fit, alignment, stability, and access details (doors, panels, clearances). Any issues are logged and corrected before packing.Typical checkpoints include hardware alignment, panel seams, and access clearances.

How early should fabrication start before a show?

Earlier is safer for custom builds. Pre-build checks also require buffer time for adjustments before packing and shipping.

Can you fabricate only specific parts (counters, walls, frames)?

Yes. We can fabricate selected modules as long as interfaces and connection logic are defined for on-site integration.

How do you package modules for faster installation?

We label modules, align packing order with the install sequence, and provide a packing list so crews can unpack in the right order.

What if the venue has strict rules (union labor, move-in windows)?

We surface constraints early and adapt build logic, labeling, and install sequencing so execution stays predictable under tight windows.

Can you fabricate a booth based on an existing design file?

Yes. We review buildability (materials, connections, tolerances) and convert the design into a fabrication-ready module plan before production.

What exactly happens in a pre-build check?

We verify fit, alignment, stability, and access details (doors, panels, clearances). Any issues are logged and corrected before packing.Typical checkpoints include hardware alignment, panel seams, and access clearances.

How early should fabrication start before a show?

Earlier is safer for custom builds. Pre-build checks also require buffer time for adjustments before packing and shipping.

Can you fabricate only specific parts (counters, walls, frames)?

Yes. We can fabricate selected modules as long as interfaces and connection logic are defined for on-site integration.

How do you package modules for faster installation?

We label modules, align packing order with the install sequence, and provide a packing list so crews can unpack in the right order.

What if the venue has strict rules (union labor, move-in windows)?

We surface constraints early and adapt build logic, labeling, and install sequencing so execution stays predictable under tight windows.

Ready to confirm your fabrication scope?

Ready to confirm your fabrication scope?

Share booth size, show city, and what you already have—we’ll map a build-ready path with pre-build checkpoints and a clean packing plan.

Visit: Circle Exhibit →

Visit: Circle Exhibit →