OUR SERVICES

OUR SERVICES

On-site Installation & Dismantle (I&D)

On-site installation and dismantle executed within venue rules, union labor requirements, and fixed move-in / move-out windows.

OUR SERVICES

On-site Installation & Dismantle (I&D)

On-site installation and dismantle executed within venue rules, union labor requirements, and fixed move-in / move-out windows.

What’s Included

This module focuses on executing booth installation and dismantle on the show floor—coordinating labor, sequencing builds, and resolving on-site issues within strict venue and time constraints.

Union labor coordination and on-site supervision

Install sequencing based on approved drawings and module IDs

Real-time issue resolution (fit, access, alignment, visibility)

Electrical, rigging, and venue compliance coordination (as scoped)

Daily progress checks against install / dismantle windows

Dismantle planning aligned with outbound logistics and reuse strategy

Deliverables You Receive

Deliverables You Receive

These are the on-site execution deliverables provided during installation and dismantle to ensure schedule control, compliance, and build accuracy.

These are the on-site execution deliverables provided during installation and dismantle to ensure schedule control, compliance, and build accuracy.

On-site Installation Supervision

Dedicated on-site oversight to coordinate labor, sequencing, and daily execution against approved plans.

On-site Installation Supervision

Dedicated on-site oversight to coordinate labor, sequencing, and daily execution against approved plans.

On-site Installation Supervision

Dedicated on-site oversight to coordinate labor, sequencing, and daily execution against approved plans.

Install & Dismantle Schedule Alignment

Execution aligned to venue move-in / move-out windows and labor call times to avoid delays or overtime risk.

Install & Dismantle Schedule Alignment

Execution aligned to venue move-in / move-out windows and labor call times to avoid delays or overtime risk.

Install & Dismantle Schedule Alignment

Execution aligned to venue move-in / move-out windows and labor call times to avoid delays or overtime risk.

Union Labor Coordination (As Required)

On-site coordination with union crews to ensure tasks follow venue rules, scopes, and approved work sequences.

Union Labor Coordination (As Required)

On-site coordination with union crews to ensure tasks follow venue rules, scopes, and approved work sequences.

Union Labor Coordination (As Required)

On-site coordination with union crews to ensure tasks follow venue rules, scopes, and approved work sequences.

Real-time Issue Resolution

Immediate handling of fit, access, alignment, visibility, or clearance issues discovered during build.

Real-time Issue Resolution

Immediate handling of fit, access, alignment, visibility, or clearance issues discovered during build.

Real-time Issue Resolution

Immediate handling of fit, access, alignment, visibility, or clearance issues discovered during build.

Dismantle Sequencing & Outbound Handoff

Controlled dismantle process aligned with packing, outbound logistics, and reuse or storage planning.

Dismantle Sequencing & Outbound Handoff

Controlled dismantle process aligned with packing, outbound logistics, and reuse or storage planning.

Dismantle Sequencing & Outbound Handoff

Controlled dismantle process aligned with packing, outbound logistics, and reuse or storage planning.

Post-show Execution Notes

Documentation of on-site adjustments, damage checks, and recommendations for future installs or reuse.

Post-show Execution Notes

Documentation of on-site adjustments, damage checks, and recommendations for future installs or reuse.

Post-show Execution Notes

Documentation of on-site adjustments, damage checks, and recommendations for future installs or reuse.

Why On-site Execution Decides the Outcome

Most delays and rework happen on-site—tight windows, complex rules, many parties, last-minute changes. We reduce uncertainty with process and checkpoints.

Most delays and rework happen on-site—tight windows, complex rules, many parties, last-minute changes. We reduce uncertainty with process and checkpoints.

Most delays and rework happen on-site—tight windows, complex rules, many parties, last-minute changes. We reduce uncertainty with process and checkpoints.

Move-in windows are fixed and unforgiving

Lost install time cannot be recovered once venue access closes.

Move-in windows are fixed and unforgiving

Lost install time cannot be recovered once venue access closes.

Move-in windows are fixed and unforgiving

Lost install time cannot be recovered once venue access closes.

Union labor rules vary by venue

Incorrect task sequencing or scope assumptions can cause immediate stoppages or added costs.

Union labor rules vary by venue

Incorrect task sequencing or scope assumptions can cause immediate stoppages or added costs.

Union labor rules vary by venue

Incorrect task sequencing or scope assumptions can cause immediate stoppages or added costs.

Small on-site issues escalate quickly

Minor fit or access problems can delay electrical, rigging, and neighboring installs.

Small on-site issues escalate quickly

Minor fit or access problems can delay electrical, rigging, and neighboring installs.

Small on-site issues escalate quickly

Minor fit or access problems can delay electrical, rigging, and neighboring installs.

Poor dismantle execution increases long-term costs

Unplanned dismantle leads to damage, loss, and reduced reuse value.

Poor dismantle execution increases long-term costs

Unplanned dismantle leads to damage, loss, and reduced reuse value.

Poor dismantle execution increases long-term costs

Unplanned dismantle leads to damage, loss, and reduced reuse value.

Controlled execution protects schedule and assets

Structured on-site management ensures the booth installs cleanly—and comes back intact.

Controlled execution protects schedule and assets

Structured on-site management ensures the booth installs cleanly—and comes back intact.

Controlled execution protects schedule and assets

Structured on-site management ensures the booth installs cleanly—and comes back intact.

How We Run On-site I&D

We run delivery by milestones and checkpoints—not by brute force.

How We Run On-site I&D

We run delivery by milestones and checkpoints—not by brute force.

How We Run On-site I&D

We run delivery by milestones and checkpoints—not by brute force.

Step 1

Pre-move-in confirmation

Confirm drawings, plans, packing list, appointed vendor interfaces, and credentials.

Step 2

On-site positioning & verification

Verify footprint, floor conditions, and key utilities on-site.

Step 3

Build & systems installation

Structure → electrical/AV → graphics → finishing in a controlled sequence.

Step 4

Pre-show checks & closeout

Power tests, stability, alignment, and finish checks—issues closed before opening.

Step 5

Dismantle, recovery & reuse prep

Teardown sequence, packing labels, return logistics, and reuse notes completed.

Step 1

Pre-move-in confirmation

Confirm drawings, plans, packing list, appointed vendor interfaces, and credentials.

Step 2

On-site positioning & verification

Verify footprint, floor conditions, and key utilities on-site.

Step 3

Build & systems installation

Structure → electrical/AV → graphics → finishing in a controlled sequence.

Step 4

Pre-show checks & closeout

Power tests, stability, alignment, and finish checks—issues closed before opening.

Step 5

Dismantle, recovery & reuse prep

Teardown sequence, packing labels, return logistics, and reuse notes completed.

Step 1

Pre-move-in confirmation

Confirm drawings, plans, packing list, appointed vendor interfaces, and credentials.

Step 2

On-site positioning & verification

Verify footprint, floor conditions, and key utilities on-site.

Step 3

Build & systems installation

Structure → electrical/AV → graphics → finishing in a controlled sequence.

Step 4

Pre-show checks & closeout

Power tests, stability, alignment, and finish checks—issues closed before opening.

Step 5

Dismantle, recovery & reuse prep

Teardown sequence, packing labels, return logistics, and reuse notes completed.

What We Need From You

Clear inputs allow us to execute installation efficiently within union labor rules and venue time windows.

Show/venue, booth number, move-in/out windows

Booth size + official rules (height, power, rigging, etc.)

Appointed vendors list + coordination contacts

Final drawings + BOM with critical dimensions

Brand assets + install priorities (materials/finishes/color)

On-site contacts + decision/sign-off owner

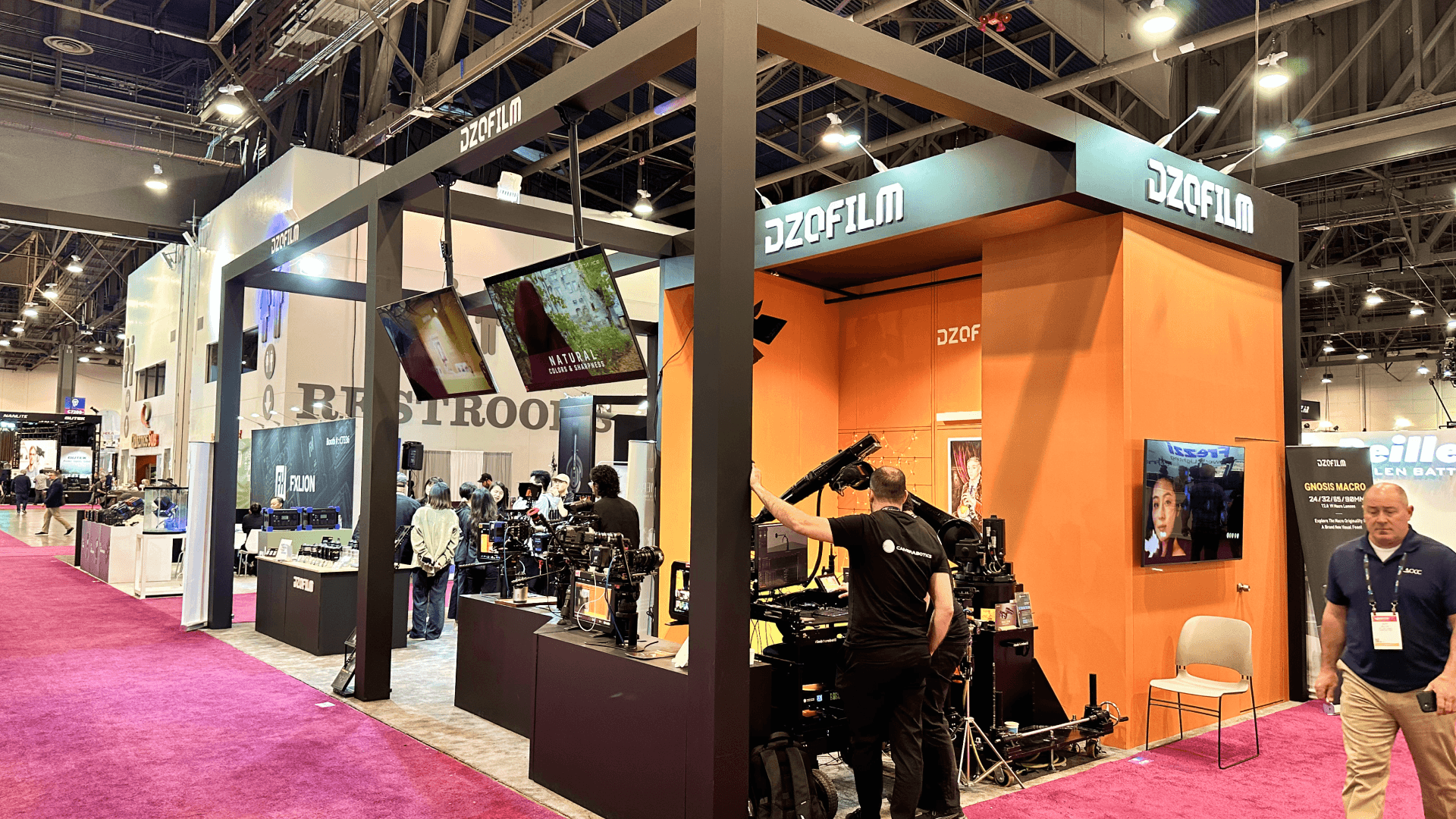

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Related Pages

Related Pages

View Case Studies

Explore real booth builds by size, complexity, and execution approach.

Back to Services

Back to Services

Back to Services

View all service modules and end-to-end delivery scope.

Browse Trade Shows

Planning notes and venue considerations for major trade shows.

Las Vegas Execution Reference

Local labor rules, drayage flow, and on-site coordination in Las Vegas.

Frequently Asked Questions

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Do you coordinate union labor and venue rules during installation?

Yes. We plan the install workflow around venue requirements and union labor rules, including what tasks must be done by union crews, when your team can access the booth, and how check-in and supervision typically work on show site.

What happens during move-in, and what do you handle on-site?

During move-in, we coordinate unloading, staging, booth assembly, and daily progress checkpoints. On-site coverage focuses on installation sequencing, crew coordination, and resolving issues that can delay the booth opening (missing parts, alignment, electrical/rigging dependencies, and last-minute changes).

How do you prevent delays when the venue’s install window is tight?

We reduce delays by using an install sequence plan, labeled parts and packing lists, and “critical path” checkpoints (structure first, then electrical/AV, then graphics, then final finish). If the venue schedule shifts, we prioritize work that protects opening readiness.

What information do you need before you arrive on-site to install?

We need the booth footprint and configuration, move-in window and targeted completion time, exhibitor-appointed contractor (EAC) requirements if applicable, any rigging/electrical needs, and the final approved layout and build details. Clear inputs reduce rework and on-site waiting.

What does dismantle include, and how do you prepare the booth for reuse?

Dismantle includes a controlled tear-down sequence, repacking by module, protection for reusable components, and labeling for storage and the next installation. This helps preserve graphics and finishes, avoids missing hardware, and shortens the next show’s install time.

Can you manage on-site changes if we adjust messaging or layout during the show?

Yes—within venue rules and the approved scope. For common changes (graphic swaps, small layout adjustments, hardware alignment, quick repairs), we handle updates with minimal disruption. For larger changes, we assess feasibility against time, labor rules, and safety constraints before proceeding.

Do you coordinate union labor and venue rules during installation?

Yes. We plan the install workflow around venue requirements and union labor rules, including what tasks must be done by union crews, when your team can access the booth, and how check-in and supervision typically work on show site.

What happens during move-in, and what do you handle on-site?

During move-in, we coordinate unloading, staging, booth assembly, and daily progress checkpoints. On-site coverage focuses on installation sequencing, crew coordination, and resolving issues that can delay the booth opening (missing parts, alignment, electrical/rigging dependencies, and last-minute changes).

How do you prevent delays when the venue’s install window is tight?

We reduce delays by using an install sequence plan, labeled parts and packing lists, and “critical path” checkpoints (structure first, then electrical/AV, then graphics, then final finish). If the venue schedule shifts, we prioritize work that protects opening readiness.

What information do you need before you arrive on-site to install?

We need the booth footprint and configuration, move-in window and targeted completion time, exhibitor-appointed contractor (EAC) requirements if applicable, any rigging/electrical needs, and the final approved layout and build details. Clear inputs reduce rework and on-site waiting.

What does dismantle include, and how do you prepare the booth for reuse?

Dismantle includes a controlled tear-down sequence, repacking by module, protection for reusable components, and labeling for storage and the next installation. This helps preserve graphics and finishes, avoids missing hardware, and shortens the next show’s install time.

Can you manage on-site changes if we adjust messaging or layout during the show?

Yes—within venue rules and the approved scope. For common changes (graphic swaps, small layout adjustments, hardware alignment, quick repairs), we handle updates with minimal disruption. For larger changes, we assess feasibility against time, labor rules, and safety constraints before proceeding.

Do you coordinate union labor and venue rules during installation?

Yes. We plan the install workflow around venue requirements and union labor rules, including what tasks must be done by union crews, when your team can access the booth, and how check-in and supervision typically work on show site.

What happens during move-in, and what do you handle on-site?

During move-in, we coordinate unloading, staging, booth assembly, and daily progress checkpoints. On-site coverage focuses on installation sequencing, crew coordination, and resolving issues that can delay the booth opening (missing parts, alignment, electrical/rigging dependencies, and last-minute changes).

How do you prevent delays when the venue’s install window is tight?

We reduce delays by using an install sequence plan, labeled parts and packing lists, and “critical path” checkpoints (structure first, then electrical/AV, then graphics, then final finish). If the venue schedule shifts, we prioritize work that protects opening readiness.

What information do you need before you arrive on-site to install?

We need the booth footprint and configuration, move-in window and targeted completion time, exhibitor-appointed contractor (EAC) requirements if applicable, any rigging/electrical needs, and the final approved layout and build details. Clear inputs reduce rework and on-site waiting.

What does dismantle include, and how do you prepare the booth for reuse?

Dismantle includes a controlled tear-down sequence, repacking by module, protection for reusable components, and labeling for storage and the next installation. This helps preserve graphics and finishes, avoids missing hardware, and shortens the next show’s install time.

Can you manage on-site changes if we adjust messaging or layout during the show?