OUR SERVICES

OUR SERVICES

Trade Show Logistics & Pre-show Coordination

Shipping coordination, move-in planning, drayage timing, and pre-show logistics checklists—built to prevent show-site delays.

We turn booth scope into a clear logistics plan: ship method, delivery window (advance warehouse or direct-to-show), on-site release timing, and install-ready sequencing—so your team walks in with a predictable move-in path.

OUR SERVICES

Trade Show Logistics & Pre-show Coordination

Shipping coordination, move-in planning, drayage timing, and pre-show logistics checklists—built to prevent show-site delays.

If you need reliable trade show booth design with engineering that actually builds, we align design decisions with real-world constraints to reduce rework and on-site uncertainty.

What’s Included

This module focuses on planning and coordinating all logistics activities before the show, ensuring materials arrive on schedule and align with venue, labor, and installation requirements.

Freight and shipping coordination (advance warehouse or direct-to-show)

Move-in / move-out window alignment

Drayage routing and dock procedure prep

Packing list, labeling, and box-level identification

Installation window alignment with venue and labor schedules

Risk checks for delays, access limits, and material readiness

Logistics Deliverables for Pre-show Execution

Logistics Deliverables for Pre-show Execution

Documents and checklists your team and vendors can follow without re-explaining the plan on-site.

Documents and checklists your team and vendors can follow without re-explaining the plan on-site.

Layout Planning & Traffic Flow

A booth layout that maps entrances, focal points, product zones, storage, and staff flow—so visitors move naturally and the team can work efficiently.

Layout Planning & Traffic Flow

A booth layout that maps entrances, focal points, product zones, storage, and staff flow—so visitors move naturally and the team can work efficiently.

Layout Planning & Traffic Flow

A booth layout that maps entrances, focal points, product zones, storage, and staff flow—so visitors move naturally and the team can work efficiently.

3D Concept Direction

3D views and key angles that define look, height, and focal moments—used as a shared reference before engineering and fabrication begin.

3D Concept Direction

3D views and key angles that define look, height, and focal moments—used as a shared reference before engineering and fabrication begin.

3D Concept Direction

3D views and key angles that define look, height, and focal moments—used as a shared reference before engineering and fabrication begin.

Structure & Materials Approach

A practical structure/material plan aligned with buildability, transport, and show rules—helping avoid fragile designs and last-minute changes.

Structure & Materials Approach

A practical structure/material plan aligned with buildability, transport, and show rules—helping avoid fragile designs and last-minute changes.

Structure & Materials Approach

A practical structure/material plan aligned with buildability, transport, and show rules—helping avoid fragile designs and last-minute changes.

Buildability & Risk Checks

Early checks on spans, loads, connections, and tricky details—flagging high-risk elements before they become on-site problems.

Buildability & Risk Checks

Early checks on spans, loads, connections, and tricky details—flagging high-risk elements before they become on-site problems.

Buildability & Risk Checks

Early checks on spans, loads, connections, and tricky details—flagging high-risk elements before they become on-site problems.

Production-Ready Drawings & Key Details

Build-ready drawings and detail callouts that guide fabrication—so the shop can produce consistently without relying on guesswork.

Production-Ready Drawings & Key Details

Build-ready drawings and detail callouts that guide fabrication—so the shop can produce consistently without relying on guesswork.

Production-Ready Drawings & Key Details

Build-ready drawings and detail callouts that guide fabrication—so the shop can produce consistently without relying on guesswork.

Execution Handoff Checklist

A handoff checklist covering what to build, pack, ship, and install—keeping design intent intact through fabrication, logistics, and install.

Execution Handoff Checklist

A handoff checklist covering what to build, pack, ship, and install—keeping design intent intact through fabrication, logistics, and install.

Execution Handoff Checklist

A handoff checklist covering what to build, pack, ship, and install—keeping design intent intact through fabrication, logistics, and install.

Why This Matters

Logistics mistakes don’t look dramatic—until they turn into missed windows, dock holds, and idle labor.

Logistics mistakes don’t look dramatic—until they turn into missed windows, dock holds, and idle labor.

Logistics mistakes don’t look dramatic—until they turn into missed windows, dock holds, and idle labor.

Move-in Windows Are Non-Negotiable

Move-in appointments, target times, and dock availability decide whether your freight can enter the hall. A small miss can trigger waiting fees, re-check-in, or a full-day delay—especially at high-traffic venues.

Move-in Windows Are Non-Negotiable

Move-in appointments, target times, and dock availability decide whether your freight can enter the hall. A small miss can trigger waiting fees, re-check-in, or a full-day delay—especially at high-traffic venues.

Move-in Windows Are Non-Negotiable

Move-in appointments, target times, and dock availability decide whether your freight can enter the hall. A small miss can trigger waiting fees, re-check-in, or a full-day delay—especially at high-traffic venues.

Drayage Rules Decide Cost and Timing

Drayage isn’t “optional shipping”—it’s the venue’s material handling process, with pricing units, labels, and delivery procedures. Clear drayage planning prevents surprise charges and ensures your crates land where your install crew expects them.

Drayage Rules Decide Cost and Timing

Drayage isn’t “optional shipping”—it’s the venue’s material handling process, with pricing units, labels, and delivery procedures. Clear drayage planning prevents surprise charges and ensures your crates land where your install crew expects them.

Drayage Rules Decide Cost and Timing

Drayage isn’t “optional shipping”—it’s the venue’s material handling process, with pricing units, labels, and delivery procedures. Clear drayage planning prevents surprise charges and ensures your crates land where your install crew expects them.

Carrier Check-in & Marshaling Yard Delays Add Up

Many venues require carrier check-in, staging at a marshaling yard, and strict arrival sequencing. If paperwork, labels, or timing is off, freight can sit—while your labor clock starts running.

Carrier Check-in & Marshaling Yard Delays Add Up

Many venues require carrier check-in, staging at a marshaling yard, and strict arrival sequencing. If paperwork, labels, or timing is off, freight can sit—while your labor clock starts running.

Carrier Check-in & Marshaling Yard Delays Add Up

Many venues require carrier check-in, staging at a marshaling yard, and strict arrival sequencing. If paperwork, labels, or timing is off, freight can sit—while your labor clock starts running.

Last-Minute Scope Changes Break the Shipping Plan

A late change in booth layout, graphics, or demo equipment often changes crate count, weights, and handling needs. Locking scope early protects your shipping method, delivery window, and on-site install sequence.

Last-Minute Scope Changes Break the Shipping Plan

A late change in booth layout, graphics, or demo equipment often changes crate count, weights, and handling needs. Locking scope early protects your shipping method, delivery window, and on-site install sequence.

Last-Minute Scope Changes Break the Shipping Plan

A late change in booth layout, graphics, or demo equipment often changes crate count, weights, and handling needs. Locking scope early protects your shipping method, delivery window, and on-site install sequence.

A Real Contingency Plan Protects Opening Day

Weather, carrier delays, or dock congestion happen. A workable plan includes buffer timing, backup delivery options (advance warehouse vs direct-to-show), and clear “what to do next” steps so you don’t lose your show floor day.

A Real Contingency Plan Protects Opening Day

Weather, carrier delays, or dock congestion happen. A workable plan includes buffer timing, backup delivery options (advance warehouse vs direct-to-show), and clear “what to do next” steps so you don’t lose your show floor day.

A Real Contingency Plan Protects Opening Day

Weather, carrier delays, or dock congestion happen. A workable plan includes buffer timing, backup delivery options (advance warehouse vs direct-to-show), and clear “what to do next” steps so you don’t lose your show floor day.

Deliverables You Receive

Deliverables You Receive

Deliverables You Receive

Practical documents that support shipping, move-in execution, and post-show recovery.

Practical documents that support shipping, move-in execution, and post-show recovery.

Freight Plan & Timeline

Shipping method, target dispatch dates, delivery milestones, buffer suggestions.

Freight Plan & Timeline

Shipping method, target dispatch dates, delivery milestones, buffer suggestions.

Freight Plan & Timeline

Shipping method, target dispatch dates, delivery milestones, buffer suggestions.

Packing List & Box Index

Itemized list with crate/box IDs and what’s inside each unit.

Packing List & Box Index

Itemized list with crate/box IDs and what’s inside each unit.

Packing List & Box Index

Itemized list with crate/box IDs and what’s inside each unit.

Labeling & Destination Map

Label format, destination zones, “open-first” marking, fragile notes.

Labeling & Destination Map

Label format, destination zones, “open-first” marking, fragile notes.

Labeling & Destination Map

Label format, destination zones, “open-first” marking, fragile notes.

Move-in Day Checklist

Documents, access needs, tools, sequence notes for the first build hours.

Move-in Day Checklist

Documents, access needs, tools, sequence notes for the first build hours.

Move-in Day Checklist

Documents, access needs, tools, sequence notes for the first build hours.

Drayage / Dock Notes

Routing notes, dock procedure reminders, receiving instructions.

Drayage / Dock Notes

Routing notes, dock procedure reminders, receiving instructions.

Drayage / Dock Notes

Routing notes, dock procedure reminders, receiving instructions.

Move-out & Recovery Notes

Re-pack guidance, return labels, missing-parts prevention notes.

Move-out & Recovery Notes

Re-pack guidance, return labels, missing-parts prevention notes.

Move-out & Recovery Notes

Re-pack guidance, return labels, missing-parts prevention notes.

How We Take Logistics From Plan to Move-in

A step-by-step workflow to keep freight, timing, and on-site sequencing aligned.

How We Take Logistics From Plan to Move-in

A step-by-step workflow to keep freight, timing, and on-site sequencing aligned.

How We Take Logistics From Plan to Move-in

A step-by-step workflow to keep freight, timing, and on-site sequencing aligned.

Step 1

Pre-show logistics scope confirmation

Confirm booth size, venue, show schedule, special handling needs.

Step 2

Shipping method & delivery window planning

Decide shipping method and define dispatch / arrival targets with buffers.

Step 3

Drayage and on-site coordination review

Group items by installation sequence and destination zones.

Step 4

Risk checks and contingency planning

Check lists, documents, and “first-in” crates readiness before dispatch.

Step 5

Final logistics release for move-in

Guide staging, sequence, and capture recovery notes for reuse.

Step 1

Pre-show logistics scope confirmation

Confirm booth size, venue, show schedule, special handling needs.

Step 2

Shipping method & delivery window planning

Decide shipping method and define dispatch / arrival targets with buffers.

Step 3

Drayage and on-site coordination review

Group items by installation sequence and destination zones.

Step 4

Risk checks and contingency planning

Check lists, documents, and “first-in” crates readiness before dispatch.

Step 5

Final logistics release for move-in

Guide staging, sequence, and capture recovery notes for reuse.

Step 1

Pre-show logistics scope confirmation

Confirm booth size, venue, show schedule, special handling needs.

Step 2

Shipping method & delivery window planning

Decide shipping method and define dispatch / arrival targets with buffers.

Step 3

Drayage and on-site coordination review

Group items by installation sequence and destination zones.

Step 4

Risk checks and contingency planning

Check lists, documents, and “first-in” crates readiness before dispatch.

Step 5

Final logistics release for move-in

Guide staging, sequence, and capture recovery notes for reuse.

What We Need From You

Clear inputs help prevent last-minute shipping changes and venue delivery issues.Clear inputs allow us to coordinate logistics accurately and avoid last-minute shipping or move-in conflicts.

Show name, venue, city, and target move-in date/time

Booth size, layout type (inline/corner/island), and height expectations

Any restrictions: union rules, dock limits, rigging/electrical needs

Contact list for approvals (who signs off on plans)

On-site staffing plan (who will be present during move-in)

Special items (fragile displays, AV gear, product samples)

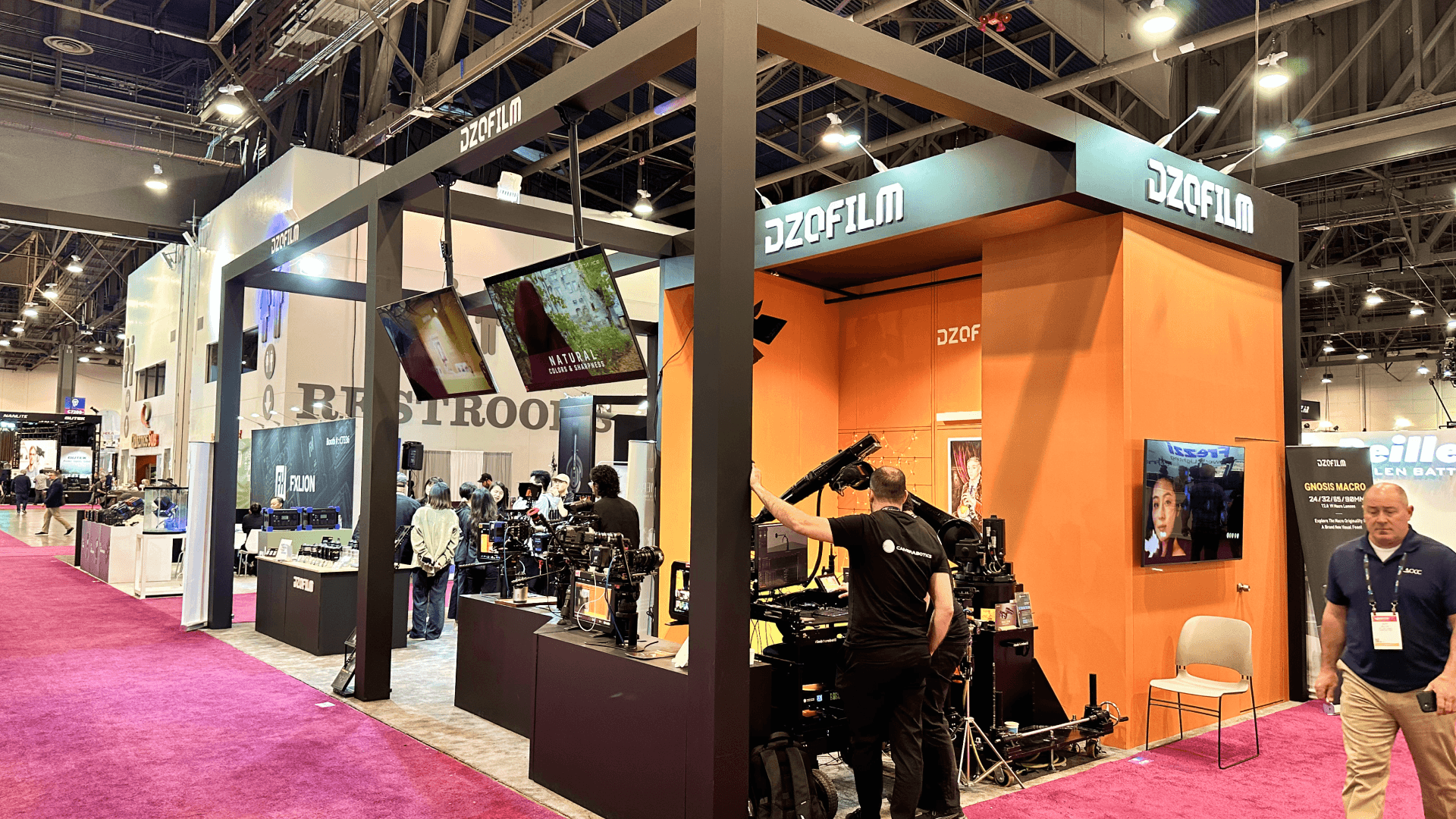

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Proof of Delivery

See real builds across sizes and complexity, including logistics-sensitive deliveries.

Related Pages

Related Pages

View Case Studies

Explore real booth builds by size, complexity, and execution approach.

Back to Services

Back to Services

Back to Services

View all service modules and end-to-end delivery scope.

Browse Trade Shows

Planning notes and venue considerations for major trade shows.

Las Vegas Execution Reference

Local labor rules, drayage flow, and on-site coordination in Las Vegas.

Frequently Asked Questions

Quick clarity on build readiness, timelines, and pre-build checkpoints.

Quick clarity on build readiness, timelines, and pre-build checkpoints.

How early should we start planning logistics?

Ideally 6–10 weeks before the show for custom builds, so shipping method, packing logic, and venue receiving can be aligned early.

Can you coordinate drayage and dock delivery requirements?

Yes—we prepare routing and receiving notes so freight arrives with clear instructions and fewer hold-ups at the venue dock.

What’s the biggest reason teams lose time during move-in?

Poor sequencing—key items are buried. A “first-in / open-first” plan helps the crew start immediately.

How do you protect graphics and finished surfaces during shipping?

We plan packing layers, edge protection, and labeling for fragile finishes so the right pieces are handled correctly at every handoff.

Can the booth ship in phases if the timeline is tight?

Often yes—phased shipping can work if the install sequence is defined early and critical path items arrive first.

Do you provide move-out and return planning for reuse?

Yes—we include recovery notes and re-pack labeling to reduce missing parts and improve next-show readiness.

How early should we start planning logistics?

Ideally 6–10 weeks before the show for custom builds, so shipping method, packing logic, and venue receiving can be aligned early.

Can you coordinate drayage and dock delivery requirements?

Yes—we prepare routing and receiving notes so freight arrives with clear instructions and fewer hold-ups at the venue dock.

What’s the biggest reason teams lose time during move-in?

Poor sequencing—key items are buried. A “first-in / open-first” plan helps the crew start immediately.

How do you protect graphics and finished surfaces during shipping?

We plan packing layers, edge protection, and labeling for fragile finishes so the right pieces are handled correctly at every handoff.

Can the booth ship in phases if the timeline is tight?

Often yes—phased shipping can work if the install sequence is defined early and critical path items arrive first.

Do you provide move-out and return planning for reuse?

Yes—we include recovery notes and re-pack labeling to reduce missing parts and improve next-show readiness.

How early should we start planning logistics?

Ideally 6–10 weeks before the show for custom builds, so shipping method, packing logic, and venue receiving can be aligned early.

Can you coordinate drayage and dock delivery requirements?

Yes—we prepare routing and receiving notes so freight arrives with clear instructions and fewer hold-ups at the venue dock.

What’s the biggest reason teams lose time during move-in?

Poor sequencing—key items are buried. A “first-in / open-first” plan helps the crew start immediately.

How do you protect graphics and finished surfaces during shipping?

We plan packing layers, edge protection, and labeling for fragile finishes so the right pieces are handled correctly at every handoff.

Can the booth ship in phases if the timeline is tight?

Often yes—phased shipping can work if the install sequence is defined early and critical path items arrive first.

Do you provide move-out and return planning for reuse?

Yes—we include recovery notes and re-pack labeling to reduce missing parts and improve next-show readiness.